People at the Center: Safer, Skilled, and Engaged

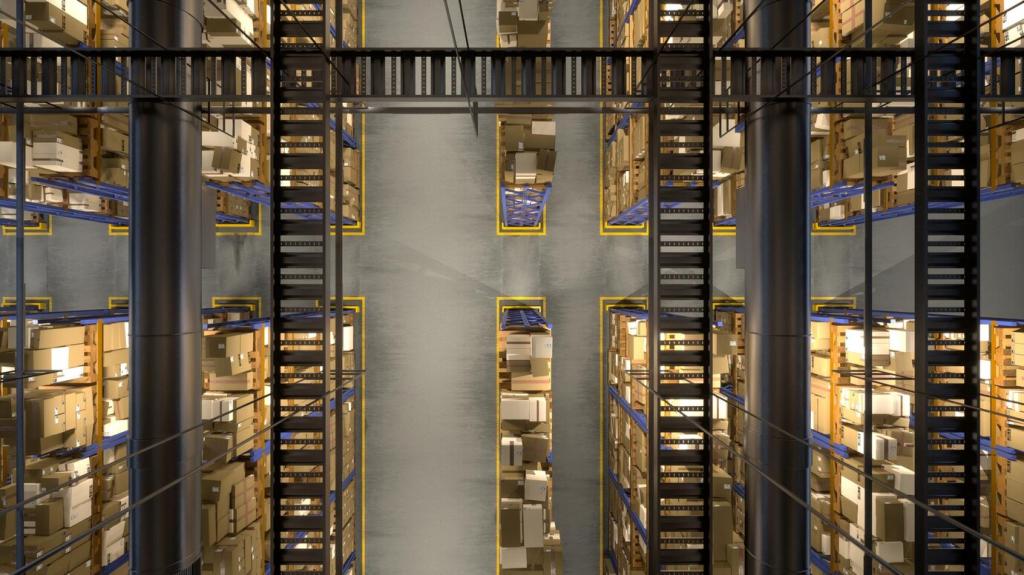

Goods-to-person stations position totes at ideal heights, reducing bending and twisting. One operator told us her shoulder pain disappeared after two weeks, turning a demanding job into sustainable, satisfying work she could confidently commit to.

People at the Center: Safer, Skilled, and Engaged

Operators become robot controllers, data analysts, and flow coordinators. Certifications in WMS, safety, and maintenance open doors internally. If you’ve transitioned roles thanks to automation, share your story to inspire others considering the leap.