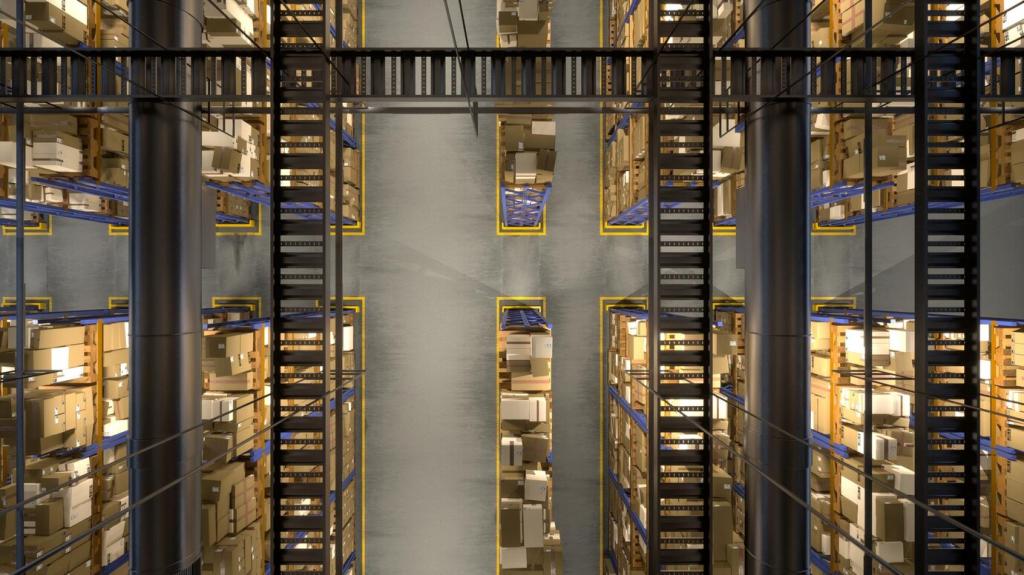

Predictive Maintenance for Conveyors, Sorters, and Forklifts

Edge sensors stream vibration spectra and motor current signatures that reveal bearing wear and misalignment days in advance. Temperature drifts often whisper long before alarms scream, giving teams breathing room.

Predictive Maintenance for Conveyors, Sorters, and Forklifts

Autoencoders or isolation forests learn normal operating patterns and flag deviations per asset, shift, and workload. Tie alerts to work orders so fixes happen before SLA penalties ever loom.

Predictive Maintenance for Conveyors, Sorters, and Forklifts

Track Overall Equipment Effectiveness and Mean Time Between Failures before and after the rollout. Transparent metrics convert skeptics, turning maintenance from a cost center into a throughput multiplier everyone celebrates.