Stories from the Aisles: Wins, Missteps, and Course Corrections

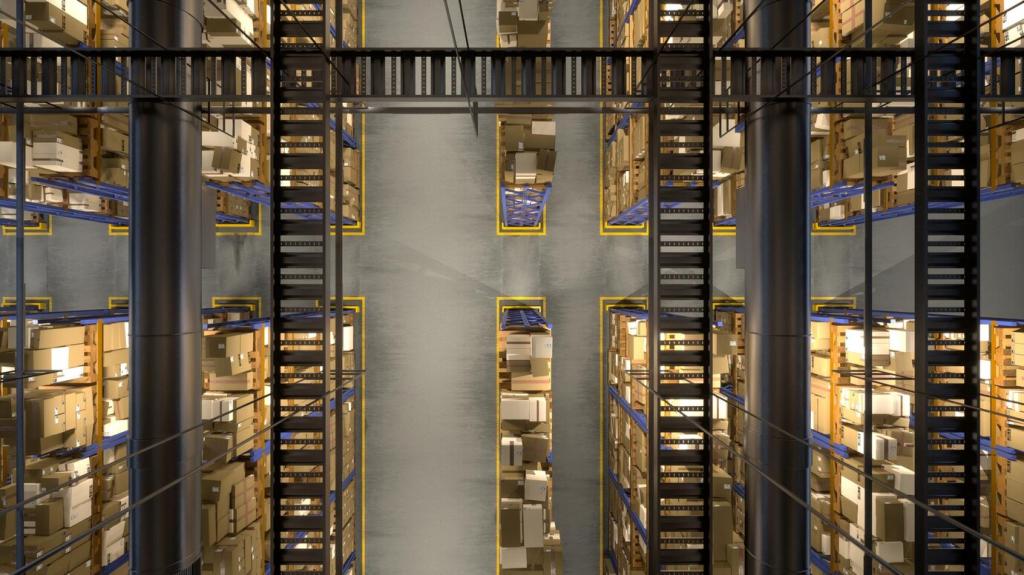

A 3PL added AMRs for zone picking and saw pick rates rise 28% in two months, then 51% by peak. Turnover dropped as walking fell dramatically. One veteran said, “Robots carry the aisle; I carry the judgment.”

Stories from the Aisles: Wins, Missteps, and Course Corrections

During peak, cloud-based orchestration reprioritized missions every minute, temporarily shifting robots to cross-dock spikes. Bottlenecks surfaced near staging lanes, prompting new buffer zones. The team shared learnings company-wide and now simulates peaks monthly to stay sharp.